The material was prepared by Tatyana Gagarina.Before developing a storage unit, think about why you need it. There are many reasons why people take on the creation of furniture based on their own sketches: non-standard room layouts, the desire to rationally manage space, optimal organization of storage volume, etc. However, you can enjoy the process if the primary motivation for "wardrobe creativity" is an irresistible desire to create a thing and test yourself in design practice. "Native" wardrobe - a great base for experiments. It can be slightly decorated or radically rebuilt if taste preferences or family circumstances change, for example, a child is born.

A look into the "magic crystal"

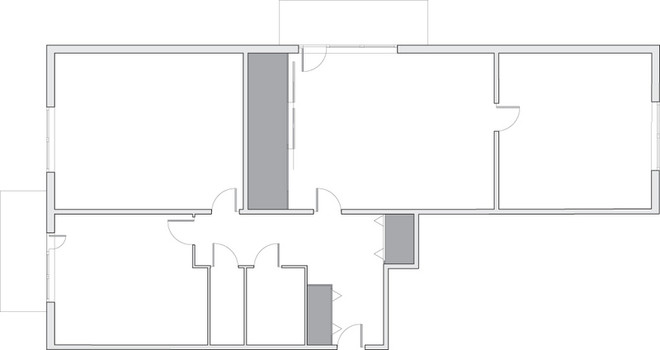

«Magic Crystal» inIn architectural creativity, the process of sketch design can be considered full of discoveries. It consists of several stages: choosing the type of construction and doors, collecting initial data (room plan, list of sections, modules, shelves, etc., information on materials and components for furniture production), creating sketches and detailed development of the final version of the project. The last stage can, and sometimes should, be delegated to professionals, but how sweet are the torments of creativity! Let's start with the general design concept. Will the wardrobe be built-in or stand-alone? The main advantage of built-in furniture is saving space, labor and materials. In essence, a strip along the wall or an area unsuitable for other purposes (for example, an irregularly shaped niche) is fenced off. The ceiling and walls of the room often act as the top panel, back and side walls. In other words, building a wardrobe comes down to erecting a facade and arranging the interior. An independent wardrobe can be either mobile or stationary. In the first case, this is a classic piece of cabinet furniture with all its inherent attributes: top, bottom, back, side and internal panels, front doors, etc. So, the type of cabinet is determined. The next step is choosing the type of doors. For built-in cabinets, it is logical to use sliding doors based on roller systems. They do not require reserving space in front of the cabinet and do not limit freedom in planning the interior (the length of the track can reach 6 m). However, in order for the doors to move smoothly and silently, it is necessary to install a high-quality system of rollers and rails made by a specialized company (Mr. Doors, Stanley, Aldo, Ecalum, Kardinal, etc.). Swing doors greatly affect the structure of cabinet furniture. They are limited in size (products more than 1 m wide and more than 2 m high are used extremely rarely). The doors are attached to the side walls and internal partitions. Thus, the division of the cabinet is tied to the width of the doors. It should be noted that traditional facades have great decorative potential. When building a wardrobe, you can use both ready-made facades (blind figured, blinds, under glass), and doors made according to the author's sketches. A worthy alternative to the swing classics - "accordion", "book". The accordion door is close in functionality to its sliding "colleague". However, the ribbed facade, as they say, "is not for everyone", besides, it eats up part of the internal volume of the wardrobe. Another thing is a "book door". The doors of this design consist of two door panels (you can use standard products), connected by a spring mechanism. The latter is part of the hinged or supporting system of folding doors. The equipment is selected taking into account the weight and dimensions of the door panels. Built-in wardrobe with your own handsArrangement of built-in wardrobes of a twelve-story block house of the II-18 series: - in the living room - in the hallway

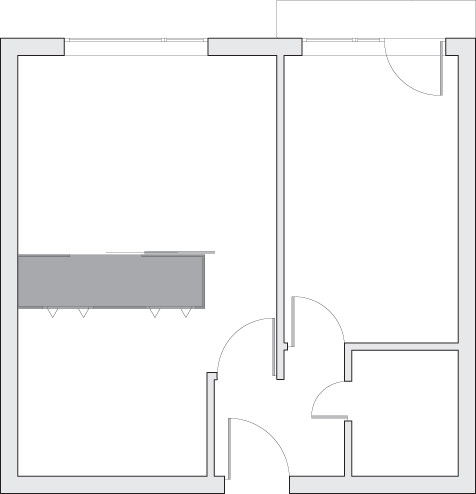

Built-in wardrobe with your own handsArrangement of built-in wardrobes of a twelve-story block house of the II-18 series: - in the living room - in the hallway Partition cabinet (house series II-18)

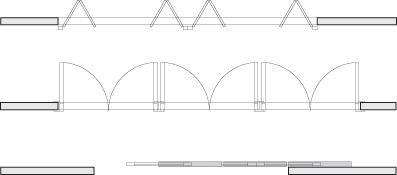

Partition cabinet (house series II-18) Door types: - folding - book - BB - swing - sliding

Door types: - folding - book - BB - swing - sliding

The treasured dossier

So, the fundamental design decisionswardrobe accepted. Here you can stop and delegate further development of furniture to professional designers. However, if the creative itch has not disappeared, then we move on to the next stage - collecting initial data. First, you need to take measurements of the part of the room where the wardrobe will be located. This work should be entrusted to the project executor. To estimate the required volume, sketch out a list of compartments, sections, sections, etc. Free planning allows each type of clothing to be allocated its place. Men's jackets and shirts can be placed in one compartment, coats, raincoats and fur coats in another, women's blouses and skirts in a third. The geometry of the modules is set taking into account the individual characteristics of the owners (height, amount of clothing). It is important that everyone who will use the wardrobe can get their things. For example, the top shelves will suit a tall and long-armed dad, and the top shelves will suit a mom and grandma. medium, and for children you can allocate a lower tier. Due to the difference in height of the compartments for long and short clothes, it is easy to save useful space. Do not forget about modern storage devices: hangers-lifts, rods-brackets, etc.

Drawing Thoughts

Armed with the initial data, let's get startedcreating sketches. If you are good at computers, then to streamline the process, use one of the graphic programs for furniture design. Specialized software will help you see a virtual closet in an existing interior from different angles and under different lighting. If this is not possible, draw a plan of the closet from above and a frontal view, which clearly shows the design with the arrangement of shelves and compartments. In passing, we note: psychologists assure that most people have a high or average level of spatial imagination. Those who are not among these lucky ones can be advised to make a model of the future closet (from cardboard, paper or a children's construction set), but this is not a task for the faint of heart. Discussion of the final version of the sketch should be brought up at a family council. As you know, one head is good, but two (or more) are better. Perhaps, during a free discussion, fresh ideas will arise. In addition, it is not uninteresting to listen to the comments of home critics. The approved sketch should be detailed. At this stage, you should finally decide on the choice of the main building materials, relying on the experience of future contractors in building the cabinet. In fairness, we note that the cabinet can be made of different elements. For example, facades made of natural wood get along well with shelves made of fiberboard, chipboard or plywood.

Helpful information

When planning the placement of shelves and drawers, consider the following:

All very seriously

Professionals in furniture designuse data on standard furniture boards sold at construction markets or in stores. If the developer's idea goes beyond the largest furniture boards or other structural modules, then building structures, such as plasterboard partitions, are used to implement it. Plasterboard elements are used to create niches, open modules, stylish design elements, etc. The choice of fasteners and the number of purchased products and materials depend on the method of connecting elements and parts (the simplest: butt, overlap; more complex: in a groove, on a tenon, "dovetail", etc.). In this case, various fasteners are used: ties, screws, studs, self-tapping screws, etc. Responsible connections are reinforced with wood glue. A special topic is fastening a cabinet to a wall. Plastic dowels with a diameter of 6 mm are suitable for a plastered brick base. If the wall is finished with plasterboard, then metal dowels with a diameter of 15 mm with a screw thread (Driva) will be required. When fastening elements of built-in furniture to concrete structures, anchor bolts are used. The installation method (fixed or adjustable) depends on the expected load. For example, adjustable shelves on stud-shaped stops or metal brackets are designed to store light items (bed linen, underwear, hats). For "solid guests" (books, porcelain services), fixed shelves fixed end-to-end and supported by reinforcing strips are suitable.

Scheduled purchases

Based on the working draft, a draft is drawn upa list of the necessary materials, fasteners and fittings. If the cabinet was not designed for ready-made furniture boards, the volume of lumber is determined taking into account rational cutting. To do this, the company's designers draw a layout of the cabinet (separately all the walls, partitions, doors, shelves) and select suitable blanks. Next, the number of fasteners and fittings (hinges, handles, clamps, brackets, drawer guides, etc.) is calculated. Let's make a reservation right away: you should not save on fittings. Preference is usually given to high-quality products from leading foreign manufacturers (Italiana Ferramenta, Giplast Group, VIBO, Volpato, Permo, Technical, Meroni Serrature, Zapet, Ferrari (all - Italy), Gamet, Marcopol (Poland), etc.). Firstly, expensive fittings give the cabinet a respectable look. Secondly, the convenience, reliability and safety of cabinet furniture depend on the technical level of the "small parts". A cabinet made of natural wood usually requires finishing. For those who prefer to admire the natural texture of wood, finishing with the application of primers, tints and varnishes is ordered.