Electric heaterOur compatriotstraditionally gravitate towards oil radiators or devices consisting of a heating coil and a fan (a la "veterok"). And for some unknown reason, they completely forget about the possibility of using such an effective and safe device as an electric convector. This "native of Europe", originally developed for primary heating, is very popular in those countries where electric heating is widespread. (There, on the basis of electric convectors, they build full-fledged heating systems for apartments, offices, houses and cottages, organizing zonal control in accordance with daily and weekly programs.) The systematic use of electric convectors in Russia today is not very widespread, although there are prerequisites for this. Mentality, however, opportunities. Historically and due to the real deficit of allocated capacities, we are focused on water central heating in the city and wood, and in the best case gas, in rural areas. We consider electric heaters only as additional heat sources or for heating summer buildings. But electric convectors have proven themselves excellent in this role as well.

Electric heaterOur compatriotstraditionally gravitate towards oil radiators or devices consisting of a heating coil and a fan (a la "veterok"). And for some unknown reason, they completely forget about the possibility of using such an effective and safe device as an electric convector. This "native of Europe", originally developed for primary heating, is very popular in those countries where electric heating is widespread. (There, on the basis of electric convectors, they build full-fledged heating systems for apartments, offices, houses and cottages, organizing zonal control in accordance with daily and weekly programs.) The systematic use of electric convectors in Russia today is not very widespread, although there are prerequisites for this. Mentality, however, opportunities. Historically and due to the real deficit of allocated capacities, we are focused on water central heating in the city and wood, and in the best case gas, in rural areas. We consider electric heaters only as additional heat sources or for heating summer buildings. But electric convectors have proven themselves excellent in this role as well.

Heaters

The heart of the electric convector –heating element. Near it, the air warms up and rises up inside the steel casing due to convection. In this case, cold air enters the convector through openings in the bottom, and warm air is thrown out through the upper ventilation grille. In modern electric convectors, there are three types of heating elements. The first, known as needle, ribbon or stitch type (from the English stitch - to sew, to quilt), is a thin plate (ribbon) made of dielectric material, densely stitched with chrome-nickel thread, which forms loops on both sides. In this case, the conductive thread is covered with a special insulating varnish, and its operating temperature is quite high. The needle heater is characterized by minimal thermal inertia: it heats up and cools down almost instantly.

The heart of the electric convector –heating element. Near it, the air warms up and rises up inside the steel casing due to convection. In this case, cold air enters the convector through openings in the bottom, and warm air is thrown out through the upper ventilation grille. In modern electric convectors, there are three types of heating elements. The first, known as needle, ribbon or stitch type (from the English stitch - to sew, to quilt), is a thin plate (ribbon) made of dielectric material, densely stitched with chrome-nickel thread, which forms loops on both sides. In this case, the conductive thread is covered with a special insulating varnish, and its operating temperature is quite high. The needle heater is characterized by minimal thermal inertia: it heats up and cools down almost instantly.

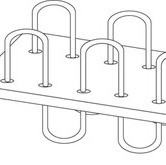

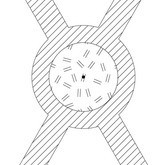

True, wire loops are not ribbing as such, so convection in such devices occurs mainly due to the design of the housing.Needle-type heating element

True, wire loops are not ribbing as such, so convection in such devices occurs mainly due to the design of the housing.Needle-type heating element

Heating element with fins

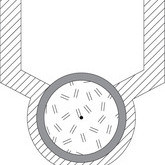

Monolithic heater

In general, «stich» – is quitedelicate thing, convectors with such a "filling" require careful transportation. And due to fragility, they are not very durable. And the practically unprotected filament is not suitable for damp rooms. As a rule, the degree of protection of devices with needle heaters is not higher than IP 21, that is, they do not have protection from splashes and dripping water. But they are the cheapest to manufacture. Such models are present in the production line of General (China), Termia (Ukraine) and even Siemens (Germany). The second type - Traditional tubular electric heaters (TENs with a nichrome filament located in a steel flask with quartz, ceramic or magnesium filling), on which aluminum fins are fixed, otherwise called a reflector or diffuser. The configuration and arrangement of the plates can vary. Developed fins provide more intense heat transfer from the heater to the air and enhances. The surface temperature of such heating elements is significantly lower than that of a hot filament. In addition, they are much more unpretentious and durable than tape ones, and are suitable for use in damp rooms. Devices with tubular heaters are produced by Ballu (China), Ensto (Finland), Nobo (Norway); Siemens, Stiebel Eltron (Germany), Thermor (France). As a rule, these devices are marked IP 24 (protection against water splashes in all directions), which means that they are approved for installation in damp rooms at a distance of at least 60 cm from open water (baths, pool edges, etc.). However, they also have their drawbacks. Due to the different thermal expansion of steel and aluminum, tubular electric heaters crackle during operation. Imperfect fit of the fins to the heating element leads to intermediate heat losses. Again, in places of attachment to the heating element, the aluminum shell can wear out over time, which will make the contact even less tight. Heating elements of the third type - monolithic - are free from these drawbacks. In them, a nichrome thread with a dielectric filler is located in a solid aluminum body with fins. This is how new models of electric convectors from Ballu; Beha, Nobo (Norway); Noirot (France) are designed. When heating and cooling, all parts of the monoblock expand and contract equally, which eliminates friction and the appearance of microcracks. The devices are silent in operation and very durable. The monolithic design made it possible to minimize intermediate heat losses and further reduce the temperature on the surface of the fins. As a rule, the protection level of models with such heaters is IP 24.