Tree Facing the facade of the house

Facing the facade of the house The only thing better than a tree is a tree —Millions of people on the planet think so. It is a living, environmentally friendly material. A wooden house is warm in winter and cool in summer (due to low thermal conductivity), it is easy to breathe in it (due to constant air exchange and constant humidity level). Wooden houses are quickly assembled and age beautifully, and all this for relatively little money. Thank God, wood is still cheaper than stone and brick in our country. If a house is built of thick logs or beams, there is no need to sheathe it. But in our climate, most buildings still need insulation, and therefore, additional finishing of the facade. At the peak of fashion today - 2014; lathing from thin beams, as well as wooden sheathing of all kinds: from planed and unplaned boards, painted, varnished, tinted, stained - especially impressive are gray antique boards that have already stood the test of time. Do not forget about the good old clapboard. True, previously, due to severe weather conditions, lack of good paints and varnishes, it was not distinguished by durability, and this led to the fact that the lining causes a persistent idiosyncrasy. Too bad. This inexpensive and environmentally friendly material has high potential. Today, it is quite possible to find weather-resistant lining made of well-dried and treated with antiseptic wood. People especially love the democratic block house - a type of rounded lining made of spruce or pine 3 or 6 m long, which gives the house the appearance of a log house. True, we do not share this love, and therefore we move on to the disadvantages of wood.

The only thing better than a tree is a tree —Millions of people on the planet think so. It is a living, environmentally friendly material. A wooden house is warm in winter and cool in summer (due to low thermal conductivity), it is easy to breathe in it (due to constant air exchange and constant humidity level). Wooden houses are quickly assembled and age beautifully, and all this for relatively little money. Thank God, wood is still cheaper than stone and brick in our country. If a house is built of thick logs or beams, there is no need to sheathe it. But in our climate, most buildings still need insulation, and therefore, additional finishing of the facade. At the peak of fashion today - 2014; lathing from thin beams, as well as wooden sheathing of all kinds: from planed and unplaned boards, painted, varnished, tinted, stained - especially impressive are gray antique boards that have already stood the test of time. Do not forget about the good old clapboard. True, previously, due to severe weather conditions, lack of good paints and varnishes, it was not distinguished by durability, and this led to the fact that the lining causes a persistent idiosyncrasy. Too bad. This inexpensive and environmentally friendly material has high potential. Today, it is quite possible to find weather-resistant lining made of well-dried and treated with antiseptic wood. People especially love the democratic block house - a type of rounded lining made of spruce or pine 3 or 6 m long, which gives the house the appearance of a log house. True, we do not share this love, and therefore we move on to the disadvantages of wood.

- Any wooden paneling does not tolerate moisture well. You can fight moisture by choosing rot-resistant species: pine, ash, oak and larch, or by laying waterproofing under the paneling layer.

- Important! Do not use poorly dried wood in construction.

- In addition to their protective properties, antiseptics can improve the appearance of wood. Colored compositions do not hide the natural texture of wood and reliably protect it from sunlight.

- The main enemy of wood is fire.Fire-retardant compounds based on aqueous solutions of salts (boric, phosphoric or silicic acids) will help to save you from it. Of course, they will not stop a strong fire, but they can slow down the spread of flames.

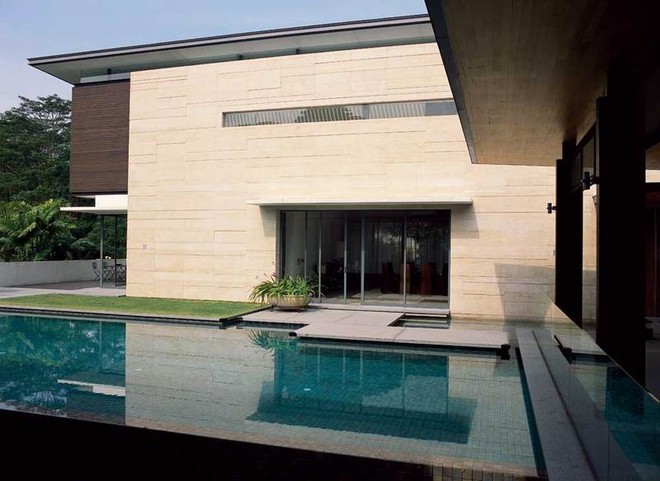

StoneOf course, the most respectable on the facadenatural stone looks. In addition, it is very practical - it is not afraid of frost and wind. To destroy stone, nature will have to work for more than one century. The most durable material is the well-known granite. Dolomite, slate, travertine and marble, which has the most shades (there are more than 200 varieties), are popular. But besides them, there are dozens of other breeds that can be used in facade decoration if desired. As a rule, stone is sold in the form of tiles cut into identical rectangles or massive slabs of natural shape. Stone tiles are usually about 2 cm thick.

- Porous limestones and sandstones are the most affordable materials, but they need to be protected from moisture with special impregnations.

- In general, any stone requires care.To do this, you need to use protective compounds from time to time, which are applied to its surface. They prevent contamination and do not allow stains to form.

- It can withstand heavy stone claddingonly a solid brick or concrete wall. The slabs are attached to a metal mesh or using ventilated facade technology, leaving a distance of about 20 cm between the wall of the house and the cladding, which will best preserve the expensive and beautiful stone.

Artificial stoneArtificial stonehas been produced for quite a long time, but only in recent years has the "substitute" approached the original in quality. The term "artificial" does not mean that the material contains any substances that are dangerous to humans. On the contrary, decorative stone, by all characteristics, is an absolutely harmless, environmentally friendly material consisting of sand, cement, fillers and dyes. Its texture can be any, but most often they buy stone with a "wild" surface that imitates river boulders or rock chips.

- Artificial stone is lighter than natural stone. Any walls can withstand it.

- Artificial stone is easy to install. It is "planted" on concrete or brickwork using special glue without preliminary preparation of the wall.

- Artificial stone is usually laid from top to bottom so as not to stain the bottom row.

- You can use this material anywhere: for cladding the entire wall, ground floor or foundation, for landscape works and objects (gazebos, grottoes and ruins).

- The artificial stone must be treated with a water-repellent solution to protect it from moisture, because in winter, water frozen in the pores can cause cracking.

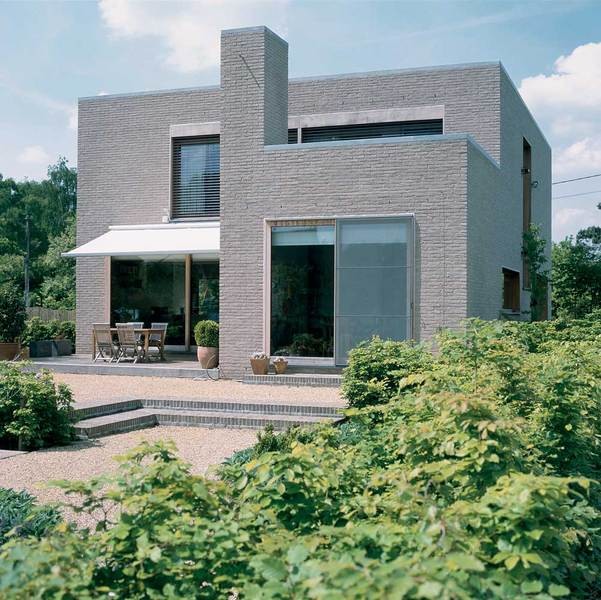

Facing brickFacing brick by compositionand similar in properties to decorative stone. It can be smooth, glazed (with a glassy colored layer), textured (with a relief pattern on the front surface) and shaped, which is used for laying complex shapes - arches, pillars, etc. One of the most spectacular options is a brick that imitates old masonry, with a relief surface and chips. Modified concrete tilesAn inexpensive (but heavy) alternative to polymer panels - modified concrete facade tiles - also imitate brick or stone masonry. This finishing material can be used on both ventilated facades and regular cement masonry.

Facing brickFacing brick by compositionand similar in properties to decorative stone. It can be smooth, glazed (with a glassy colored layer), textured (with a relief pattern on the front surface) and shaped, which is used for laying complex shapes - arches, pillars, etc. One of the most spectacular options is a brick that imitates old masonry, with a relief surface and chips. Modified concrete tilesAn inexpensive (but heavy) alternative to polymer panels - modified concrete facade tiles - also imitate brick or stone masonry. This finishing material can be used on both ventilated facades and regular cement masonry.

- The advantage of a modified concrete front tile over polymer panels is that it resembles brick or masonry not only in appearance but also in touch.

Polymer panelsFacade polymer panels from usare not very popular yet, although they look very attractive and can depict any type of stone, brick or turn into pine shingles, reproducing the rough structure of natural wood. These panels, made of modern composites, reliably protect the walls.

- They hardly change their size under the influence of temperature.

- An additional acrylic coating makes their surface fireproof, resistant to fading and prevents dirt from sticking.

- This is perhaps the only material on the installationwhich can be saved. The installation of panels is simple and will not cause difficulties even for an amateur. The panels are simply snapped into each other and secured with screws or nails. If it is impossible to mount the panels directly on the facade, they are attached to a metal frame or wooden lathing.

- During the entire period of operation, there are no signs of damage to the panels.salts will appear, they do not need to be treated with special water-repellent compounds, and they do not deteriorate when exposed to water (like, for example, facing bricks).

SidingVinyl siding is irreplaceable in a situation wherewhen you need to quickly and cheaply sheathe or re-face an old, dilapidated facade, install a ventilated facade with additional insulation. Siding repeats the structure of wooden paneling and has a range of about 15 colors, traditional for painted wood, but still remains just an imitation.

SidingVinyl siding is irreplaceable in a situation wherewhen you need to quickly and cheaply sheathe or re-face an old, dilapidated facade, install a ventilated facade with additional insulation. Siding repeats the structure of wooden paneling and has a range of about 15 colors, traditional for painted wood, but still remains just an imitation.

- Vinyl siding is loved for its ease of installation andcheapness (the panels already have holes made in them for fastening to a flat wooden lathing), for ease of maintenance - no need to paint or protect from moisture, on the contrary, you can even wash it with a hose.

- Low-quality siding quickly fades andwhen heated in the sun, it emits an unpleasant odor. A higher-quality one can last up to 50 years, but in our area, prone to temperature fluctuations, severe frosts and sudden thaws will shorten its "life".

Wooden sidingOn wooden siding, although itand is the progenitor of all types of siding, there is practically no demand in our country. And this is easily explained by stereotypes of thinking: in the minds of Russians, this material is firmly associated with clapboard, which requires constant care. In Europe and America, where everything natural is highly valued, wooden siding is considered a luxurious material, but this is not a decisive argument for our fellow citizens.

- The main disadvantage of wood siding isdislike of moisture and fear of fire - is compensated by its spectacular appearance, which, with proper care using antiseptics and varnishes, will please the eye for a long time.

Metal sidingAluminum and steelSiding options are more durable than their vinyl counterparts, but their rugged appearance is only suitable for homes in a modern style. To give a spectacular look and protect against external tests, aluminum panels are covered with PVC film or paint. Steel is protected from rust with a special varnish coating.

Metal sidingAluminum and steelSiding options are more durable than their vinyl counterparts, but their rugged appearance is only suitable for homes in a modern style. To give a spectacular look and protect against external tests, aluminum panels are covered with PVC film or paint. Steel is protected from rust with a special varnish coating.

- Aluminum and steel siding does not burn or rust.

- Aluminum siding has one drawback - it can dent if hit hard.

- Steel siding is much stronger than aluminum, although it costs about the same.

- Steel siding is heavier and can only be used if the house foundation was originally designed to withstand the additional load.

Cement sidingIn our country cement sidinghas only just begun to find its fans, although this material is almost thirty years old (it was invented by the Australian company James Hardie). Professionals agree that cement siding will soon become the second most popular finishing material after vinyl. It is made from cement with the addition of cellulose fibers. During the manufacturing process, such siding acquires a wood texture. After that, it undergoes high-temperature treatment, acquiring additional strength.

- Cement siding is not afraid of strong wind, sunlight and mold, it retains its size and shape even at maximum temperatures. It is issued a 50-year warranty.

- When installing and cutting this material, cement dust harmful to human health is formed.

Plasters There was a time when plaster was consideredthe simplest, cheapest and most primitive way of finishing walls. Traditions are not the worst thing, especially if they are supplemented with the achievements of progress. If earlier the main criterion for assessing a plastered facade was beauty, now you can’t do without sound and heat insulation requirements. Therefore, various types of fillers began to be added to the traditional material, which extend the life of the coating and improve its characteristics. Such is porous, or “warm” plaster with a special filler. The widespread opinion that this material is capricious and will have to be regularly updated is not entirely true.

Plasters There was a time when plaster was consideredthe simplest, cheapest and most primitive way of finishing walls. Traditions are not the worst thing, especially if they are supplemented with the achievements of progress. If earlier the main criterion for assessing a plastered facade was beauty, now you can’t do without sound and heat insulation requirements. Therefore, various types of fillers began to be added to the traditional material, which extend the life of the coating and improve its characteristics. Such is porous, or “warm” plaster with a special filler. The widespread opinion that this material is capricious and will have to be regularly updated is not entirely true.

- If the facade is plastered by professionals without violating the technology, the coating will last for years without fading or losing its texture.

- The plaster is resistant to mechanical loads and is a low-flammability finishing material.

- It is made from environmentally friendly components and is breathable, as it has a microporous structure.

- Plaster can be applied to any surface:concrete, cement, brick, plasterboard, wood, metal. At the same time, all surface defects (microcracks, swellings) will be skillfully masked.

- High-quality plaster is not afraid of moisture, afterAfter drying, it can be washed and cleaned with any solvent-free products, and it can withstand temperature fluctuations from -50 to +75 °C.

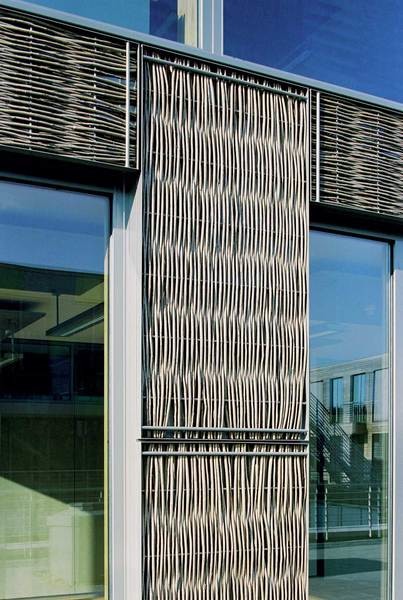

CopperFor finishing the facades of country houses copperIt is not used often yet, which is a pity, because it is one of the most durable materials. For it, 100 years is not old (unless, of course, the alloy contains destructive impurities). You can cover the facades with sheets or special snap-on cassettes (they are more suitable for a house in a modern style). Patinated (oxidized) panels will help reconcile lovers of antiquity with this metal. The owners will not have to wait long for the metal to age nobly and turn green, the house will immediately acquire a "history" imprinted on its walls. What is interesting: even after installation, the color of patinated copper continues to change. The metamorphoses that will occur with the facade over the next 10-30 years depend entirely on the composition of the alloy. Copper with aluminum will first turn a little green, but will eventually become golden. Brass, an alloy of copper and zinc, will eventually turn from a bold red-gold to a dark brown. Copper-tin alloy will first turn a grayish-red and then gradually begin to blacken.

CopperFor finishing the facades of country houses copperIt is not used often yet, which is a pity, because it is one of the most durable materials. For it, 100 years is not old (unless, of course, the alloy contains destructive impurities). You can cover the facades with sheets or special snap-on cassettes (they are more suitable for a house in a modern style). Patinated (oxidized) panels will help reconcile lovers of antiquity with this metal. The owners will not have to wait long for the metal to age nobly and turn green, the house will immediately acquire a "history" imprinted on its walls. What is interesting: even after installation, the color of patinated copper continues to change. The metamorphoses that will occur with the facade over the next 10-30 years depend entirely on the composition of the alloy. Copper with aluminum will first turn a little green, but will eventually become golden. Brass, an alloy of copper and zinc, will eventually turn from a bold red-gold to a dark brown. Copper-tin alloy will first turn a grayish-red and then gradually begin to blacken.

- Remember, no matter what the alloy, after 30 years the copper surfaces will still be covered with the classic green copper patina.

Alternative MaterialsList allfinishing materials for facades is almost impossible. This area is a vast platform for creativity. Some architects experiment with earthen blocks, recalling the adobe buildings of the past. Others do not refuse curtain walls made of glass and introduce new types of plastic into practice. Supporters of the environmental movement cover the walls of houses with old tires, which are sprinkled with earth and empty bottles. They say that the sound and heat insulation in these houses is at a height, and there is noticeably less garbage in the area. Where to buy

- Metal siding - Company "Techno Nikol": Moscow region, Lyubertsy, Transportnaya st., 2, tel. (495) 101 4611

- Metal cassettes and siding - Elko Company: Kazakova St., 31/20, entrance 1, office 7, tel. (495) 748 3565

- Panels, cassettes, sheets of copper and zinc - Company "Delos", Sadovnicheskaya st., 71, tel. (495) 505 1579

- Copper facade cassettes - Cuppro Company, tel.: (495) 334 1910, 334 1901, 228 7902

- Fiber Cement Siding & Panels - James Hardie Company

- Aluminum siding – Company «Stroyprestizh»: Golikovsky per., 8, tel.: (495) 959 4943, 953 3008

- Sandstone, limestone, natural pebbles - Poltavsky Alexander Vladimirovich, tel.: 8 921 391 3154, 344 0382

- Facing and ceramic bricks -Company "Enki Trade": TVK "STROY-CITY", basement floor, pavilion C-3, Nakhimovsky pr-t, 24, bldg. 1, tel.: (495) 129 4433, 780 7369, 647 8096

- Lining – Company «Toks»: Varshavskoe sh., 28 Zh, tel.: (495) 933 2591, 722 7029

- Artificial stone - Chelsea Stone Company: B. Semenovskaya st., 49, office 206, tel.: (495) 737 6373, 737 6391

- Clinker brick – Company «Fasad-Ceramics»: Leningradsky Prospekt, 80, entrance 3, office 601, t. (495) 363 0750

- Artificial stone – Company «Ekolit-Trade»: Nakhimovsky pr-t, 24, building 1, 2nd floor, office 203, tel. 124 7391

- Slate – STK «Everest-Izolyatsiya»: Dmitrovskoye sh., 107, t. (495) 101 3611