Stylist Maria Vatolina. Photo by Mikhail Stepanov.

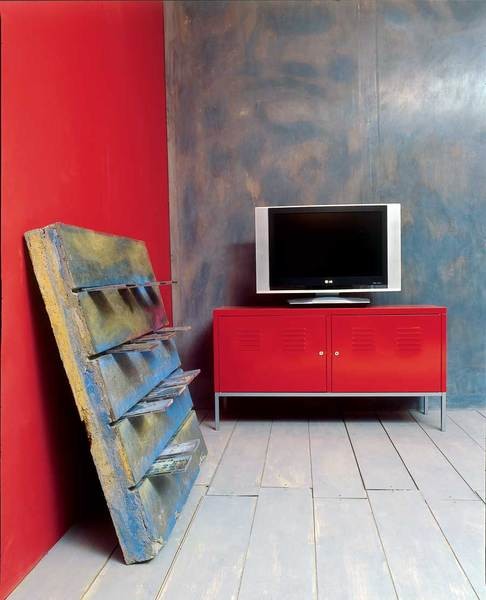

1. CD storage panel

Concrete products

Concrete products

You will need:the highest quality cement (grade 500) and fine river sand (www.shop.vira.ru) for the concrete mortar, boards or thick plywood for the formwork, reinforcement (thick steel wire or metal rods), coarse sandpaper and a grinding machine for polishing, as well as pastel crayons and water-based varnish for decorative finishing. 1. Knock together a box-shaped formwork for pouring concrete from plywood or boards with sides of 1200 x 1200 x 200 mm. The panel should not be too large, otherwise it will be fragile. 2. Put reinforcement (for strength) on the bottom of the formwork: rods or metal mesh are best. 3. Mix concrete mortar in a bucket: first mix cement and river sand (2 x 1 ratio), sift the mixture through a sieve (minimum mesh size 3 x 3 mm) and only then add water to the consistency of sour cream. 4. Pour concrete into the formwork in small portions. 5. In order to make recesses for the CD, it is important to press 15 x 15 mm slats into it at equal distances from each other without waiting for the top layer of mortar to dry. 6. After the mortar has completely dried, disassemble the form, starting with the slats. Sand the uneven edges of the panel with sandpaper or a grinding machine. To polish or not to polish? You can make a choice after the panel is removed from the form. A polished surface looks more finished and high-quality, an unpolished one - more brutal. You can further emphasize the texture of concrete using pastel crayons or water-based paint, fixing them with water-based varnish (available at all construction markets). The advantage of such a coating over nitro varnishes is that water-based varnish is absorbed into the structure of concrete without changing the appearance of the product, does not shine and does not crack after drying. Remember! To avoid cracking of the concrete surface, it is necessary to pour concrete in layers. Moreover, each layer must be thoroughly dried. You can speed up the drying process with a building hair dryer. However, you can also use special compounds - plasticizers that increase the water resistance of concrete, accelerate its hardening and prevent cracks (Extra, Lignopan, Megalit, etc.)

You will need:the highest quality cement (grade 500) and fine river sand (www.shop.vira.ru) for the concrete mortar, boards or thick plywood for the formwork, reinforcement (thick steel wire or metal rods), coarse sandpaper and a grinding machine for polishing, as well as pastel crayons and water-based varnish for decorative finishing. 1. Knock together a box-shaped formwork for pouring concrete from plywood or boards with sides of 1200 x 1200 x 200 mm. The panel should not be too large, otherwise it will be fragile. 2. Put reinforcement (for strength) on the bottom of the formwork: rods or metal mesh are best. 3. Mix concrete mortar in a bucket: first mix cement and river sand (2 x 1 ratio), sift the mixture through a sieve (minimum mesh size 3 x 3 mm) and only then add water to the consistency of sour cream. 4. Pour concrete into the formwork in small portions. 5. In order to make recesses for the CD, it is important to press 15 x 15 mm slats into it at equal distances from each other without waiting for the top layer of mortar to dry. 6. After the mortar has completely dried, disassemble the form, starting with the slats. Sand the uneven edges of the panel with sandpaper or a grinding machine. To polish or not to polish? You can make a choice after the panel is removed from the form. A polished surface looks more finished and high-quality, an unpolished one - more brutal. You can further emphasize the texture of concrete using pastel crayons or water-based paint, fixing them with water-based varnish (available at all construction markets). The advantage of such a coating over nitro varnishes is that water-based varnish is absorbed into the structure of concrete without changing the appearance of the product, does not shine and does not crack after drying. Remember! To avoid cracking of the concrete surface, it is necessary to pour concrete in layers. Moreover, each layer must be thoroughly dried. You can speed up the drying process with a building hair dryer. However, you can also use special compounds - plasticizers that increase the water resistance of concrete, accelerate its hardening and prevent cracks (Extra, Lignopan, Megalit, etc.)

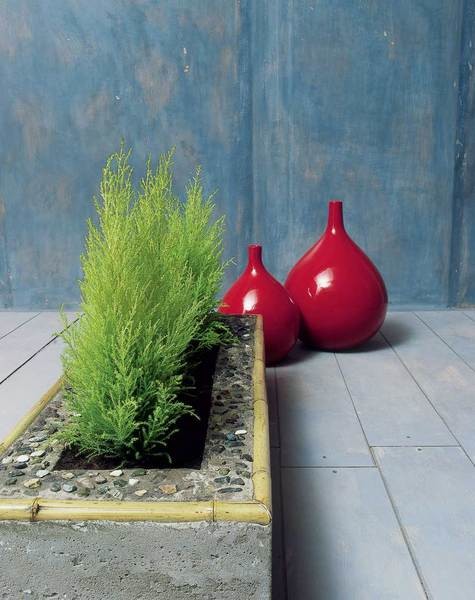

2. Concrete flower pot

The size of the flowerpot is 1200 x 400 x 200 mm.The rectangular formwork is made in the same way as the CD panel, but it is better to put a thin metal sheet on the bottom in addition to the metal rods. To simplify the work, you can immediately put a metal or plastic container for future plants in the center of the formwork. After that, concrete solution is poured into the formwork. You should decorate the flowerpot with bamboo and granite pebbles when the solution dries a little, but has not set completely.

The size of the flowerpot is 1200 x 400 x 200 mm.The rectangular formwork is made in the same way as the CD panel, but it is better to put a thin metal sheet on the bottom in addition to the metal rods. To simplify the work, you can immediately put a metal or plastic container for future plants in the center of the formwork. After that, concrete solution is poured into the formwork. You should decorate the flowerpot with bamboo and granite pebbles when the solution dries a little, but has not set completely.

3. Low coffee table

To make this table (1500 x 500 x 400mm) it is necessary to make the formwork of a more complex shape. In addition, such a large length requires stronger reinforcement. The best option is a welded structure made of thick metal rods. It will hold the stiffener and will not allow the table to break under its own weight. Candlestick, Grow-ing Veip, "Purple" salon, 10,260 rubles. The surface of the bench is laid out with marble chips (it is sold in the "Garden Center on Voykovskaya" or in flower shops) and polished. This was possible due to the fact that marble is a soft material. Polishing concrete on a large scale requires special equipment, but if you plan to polish a small concrete table, then a household grinding machine for polishing wood will do just fine. Colored concrete Concrete can be painted. There are special dyes for this: mineral (chalk, ochre, umber, whitewash, painter's soot, zinc green) and organic (yellow, red, blue pigment, artificial cinnabar). Metal powders - aluminum powder, zinc dust, golden bronze - can be used for the same purpose. To ensure that the quality of concrete does not suffer, the amount of pigment should not exceed 5% of the cement mass (1-2 kg per 100 kg of cement). The pigment is first mixed with the filler (sand), then cement and water are added. Brighter and more saturated colors are obtained on the basis of white cement.

To make this table (1500 x 500 x 400mm) it is necessary to make the formwork of a more complex shape. In addition, such a large length requires stronger reinforcement. The best option is a welded structure made of thick metal rods. It will hold the stiffener and will not allow the table to break under its own weight. Candlestick, Grow-ing Veip, "Purple" salon, 10,260 rubles. The surface of the bench is laid out with marble chips (it is sold in the "Garden Center on Voykovskaya" or in flower shops) and polished. This was possible due to the fact that marble is a soft material. Polishing concrete on a large scale requires special equipment, but if you plan to polish a small concrete table, then a household grinding machine for polishing wood will do just fine. Colored concrete Concrete can be painted. There are special dyes for this: mineral (chalk, ochre, umber, whitewash, painter's soot, zinc green) and organic (yellow, red, blue pigment, artificial cinnabar). Metal powders - aluminum powder, zinc dust, golden bronze - can be used for the same purpose. To ensure that the quality of concrete does not suffer, the amount of pigment should not exceed 5% of the cement mass (1-2 kg per 100 kg of cement). The pigment is first mixed with the filler (sand), then cement and water are added. Brighter and more saturated colors are obtained on the basis of white cement.